What is DTF printing?

DTF (direct-to-film) printing is a printing method that uses a specialized film transfer process. It lets you apply full-color designs – including gradients and fine detail – on several types of fabrics, like cotton, polyester, and blends.

At Printful, we’ve taken DTF a step further. We spent over 10 years perfecting our own DTF technique to create what we call DTFlex – the next-gen of direct-to-film printing. Its unmatched color matching, flawless finish, and sharp detail help you bring your brand to life, exactly as you envisioned it.

How does DTF printing work?

The direct-to-film printing process is simple, precise, and provides amazing quality with long-term durability.

1. Design a product

Choose a product from our catalog and go to our Design Maker. Upload your artwork or create something new from scratch with our text editor, free graphics library, pattern creator, and more. Place an order, and we’ll get right to work making the magic happen.

2. Print to film

Our DTFlex printers apply your design onto a special transfer film using water-based pigment inks.

3. Adhesive powder

The printed film is coated with a fine powder and then cured with heat to activate it.

4. Heat press

The film transfer is placed on the garment and applied with a heat press machine, bonding the ink to the fabric.

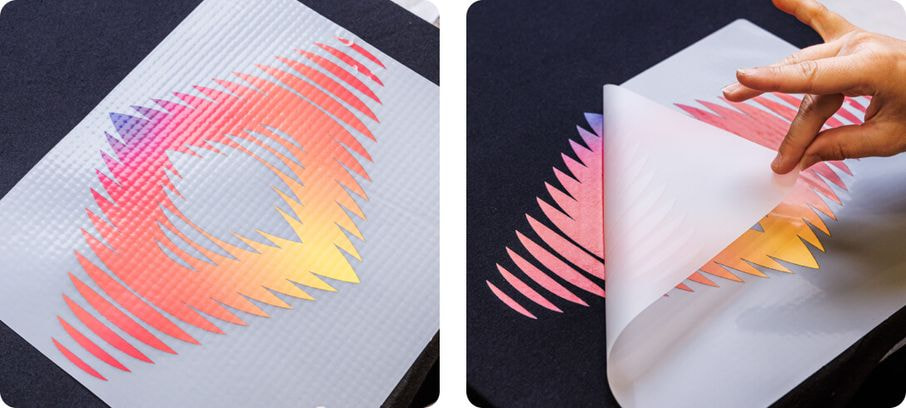

5. Cold peeling

After a few seconds, the sheet is removed using the cold peeling technique, leaving a durable, vibrant print.

DTF vs DTG: What’s the difference?

Both methods create spectacular prints, but DTF works better on a wider range of fabrics, including polyester and blends. DTG requires pretreatment and is best suited for cotton.

Create beautiful DTF products with Printful

See what others love about our DTF printing services

FAQ

DTF stands for direct-to-film. It’s a decoration method where your design is printed onto a special film, coated with adhesive powder, and then transferred to fabric using a heat press machine.

It’s ideal for producing vibrant, detailed designs on a wide range of textiles, including cotton, polyester, and blends. The most popular use is direct-to-film shirt printing.

While DTFlex uses the same core direct-to-film technique, it is our unique, refined version that uses materials and technology that are unique to Printful. We’ve spent over a decade perfecting the process to ensure consistent, high-quality results for on-demand production. Unlike regular direct-to-film printing, which can leave behind a visible glue layer, DTFlex delivers a flawless, glue-free finish for a cleaner, more premium look and feel.

DTFlex also offers superior sharpness, richer colors, and a flawless finish, making it the gold standard for merchants who prioritize quality.

It depends on the fabric and how it’s being used. DTF transfer printing works on more surfaces, including cotton and dark garments, and doesn’t require polyester-only materials. Sublimation printing, on the other hand, delivers long-lasting, perfect results but only works on light-colored polyester.

If you need more versatility and material options, or a more cost-effective method, DTF is the better fit.

No, you need a reliable, dedicated DTF printer specifically designed to work with transfer film, DTF inks, and powder adhesive.

Regular inkjet or laser printers aren’t compatible with the DTF printing process or capable of producing durable designs that withstand regular washing.

When applied properly, DTF transfers are extremely durable. They hold up through repeated wash cycles without fading, peeling, or cracking – maintaining color and clarity over time. Printful’s high-quality DTFlex prints for shirts are made to endure high friction and frequent wear.