Table of contents

If you’re in the business of creating eye-catching designs for custom t-shirts, hoodies, or mugs, you may have heard about sublimation and DTF printing. Both have gained popularity in recent years, offering amazing print quality.

In this blog post, we’ll do an in-depth DTF vs. sublimation comparison, explain how each printing method works, and what kind of products they’re best for.

From the technical steps behind the printing process to the benefits and limitations of each method, this is the guide you need to navigate the world of custom printing. Let’s dive in!

What is DTF printing?

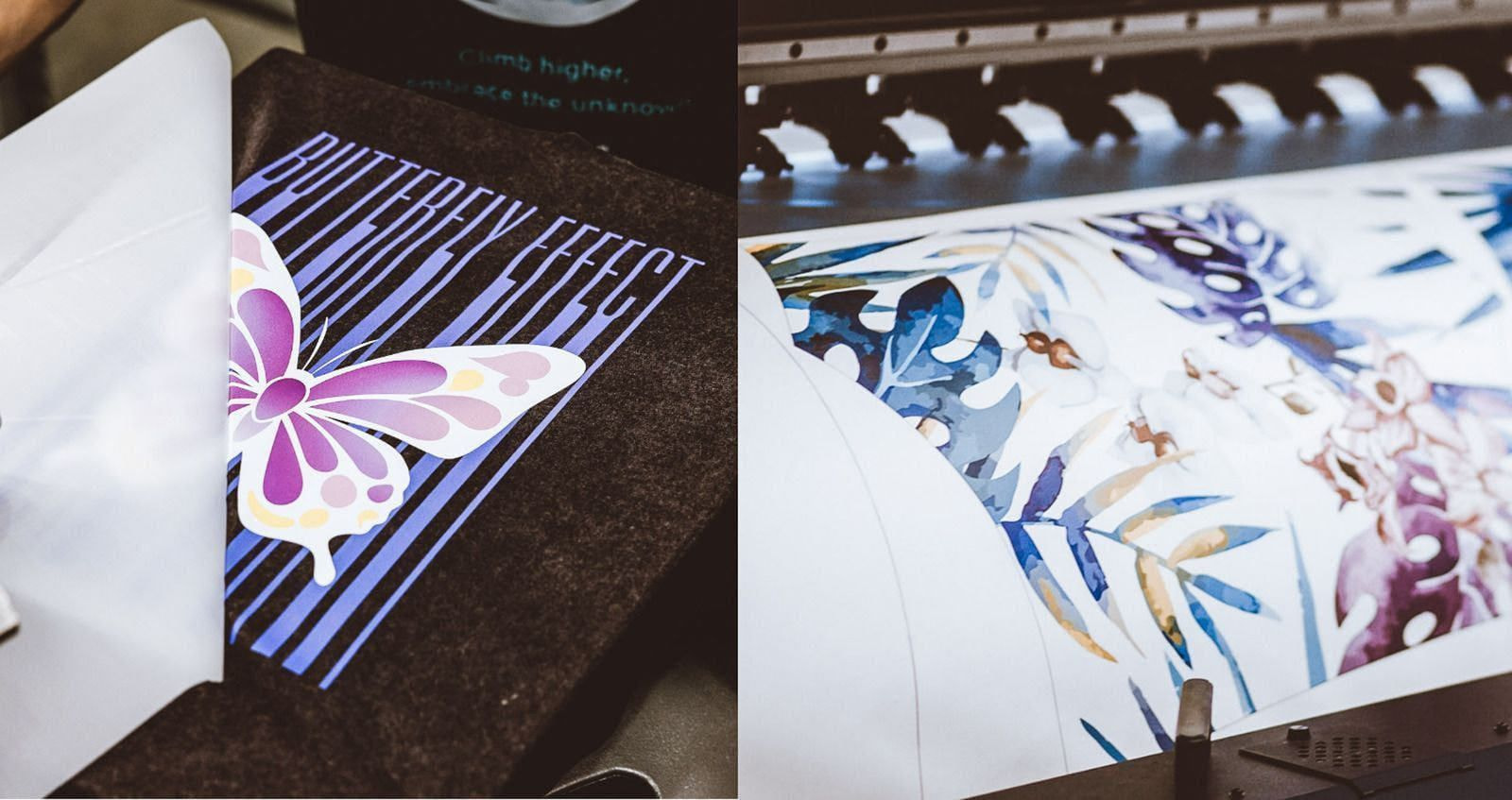

DTF is a fast-growing technique in the apparel industry, known for producing vibrant, durable prints across a variety of fabrics. Designs are printed onto transfer film with water-based inks, coated with adhesive, and then heat-pressed onto the garment for a detailed and lasting finish.

At Printful, we’ve refined this technology into DTFlex — our premium version of DTF. DTFlex is engineered for sharper details, richer colors, and flawless edges, delivering consistent, retail-quality results on demand.

How does DTF printing work?

At Printful, your design is printed onto transfer film with water-based inks, coated with a fine adhesive layer, and heat-pressed to the garment. The result — vibrant, durable prints with crisp edges, delivered on demand.

Here are the basic steps of DTF printing:

-

The design is printed onto a special transfer film with water-based inks

-

The ink on the film is then coated with adhesive powder

-

Next, the design is transferred onto the fabric using a heat press

Although the process includes multiple steps, t-shirt printing with a DTF printer is quick and takes just a few minutes.

Source: Printful

What is sublimation printing?

Sublimation printing is a technique where the design is embedded in the fabric or item using heat and sublimation ink.

It’s a popular print-on-demand method for creating all-over print products. Fabric is sublimated first, then cut and sewn together. Some of the benefits include large print areas, vivid colors, sharp details, and long-lasting prints.

How does sublimation printing work?

Sublimation printing can be a lengthy process. Here’s how it works:

-

The design is printed onto special transfer paper using sublimation ink

-

The transfer paper is placed onto the fabric and subjected to a heat press with pressure and time

-

The extremely high heat turns the sublimation ink into gas

-

The sublimation inks bind with the fabric fibers, producing durable prints

DTF printing vs. sublimation printing

Let’s go over each printing method in detail so it’s easier for you to choose the most suitable one for your printing business. From print quality to fabric suitability, here’s how DTF printing compares to sublimation.

Print quality and durability

DTF printing quality is excellent. If you want to print photos, colorful designs, graphics, or art, it’s the way to go. The ink sits on top of the fabric, so it doesn’t lose any detail or vibrancy in the printing process.

The prints come out smooth and elastic, which ensures longevity. They can handle heavy use and many washes without fading color. That said, the design may develop minor cracks if washed in very hot water. Follow our care instructions to make sure the prints maintain great color and vibrancy over time.

We don’t recommend using the DTF method for printing large areas as it can make the garment feel heavy and rigid, and reduce breathability.

Keep in mind that DTF prints might seem stiff initially, but they’ll wear in after a couple of washes. Plus, the print is thin, so it doesn’t feel too bulky. In contrast, sublimation printing doesn’t create a raised print texture on the fabric and is more comfortable to wear from the get-go.

Sublimation printing quality is also outstanding. You can print detailed images in multiple colors that will look vibrant and sharp. The color is infused into the fabric fibers, so it doesn’t fade or peel off, resulting in durable prints.

Print complexity

DTF excels where precision matters — from fine text to intricate illustrations — without requiring separate layers for each color.

But if you want to go for a large design, the DTF printing method might not be the one for you. DTF prints are not very breathable, which means that printing a large area makes the garment less comfortable for longer wear. The extra weight makes the fabric feel heavy and inflexible, and having a large printed area often just looks worse on the garment.

With sublimation printing you can also achieve detailed prints and produce designs of different complexity. It’s especially suitable for digital photos, pattern designs, gradients, and colorful artwork. Sublimation has a larger print area compared to DTF transfers, as it can cover the entire garment.

Sublimation printing works in a way that the printed image binds with the fabric (rather than sitting on top of it), providing vibrant and durable results. Since sublimation transfers dyes to materials, the finer details also come out looking sharp.

Color vibrancy

Both DTF and sublimation printing use the four primary colors (known as CMYK or cyan, magenta, yellow, and black) for their prints. This means that designs are printed in bright, vivid colors.

What’s more, you can print gradients with both methods. Printful’s DTFlex uses custom-formulated inks for truer, richer colors across dark and light garments.

There’s no white ink in sublimation printing, but its base color limitations can influence color vibrancy. For example, if you sublimate on black fabric, the colors won’t be visible. For this reason, sublimation is usually done on white or light-colored garments. In contrast, DTFlex printing offers vibrant results on any fabric color.

Fabric suitability

One of DTF’s biggest strengths is versatility. It works on cotton, polyester, fleece, nylon, and blends — giving you more fabric options than sublimation or DTG.

Source: Printful

Sublimation printing is best for light-colored polyester, polyester blends, or polymer-coated fabrics. If you’d like your design printed on natural fibers like cotton, silk, or leather, sublimation won’t be the right fit for you.

Sublimation dyes adhere better to synthetic fibers, so 100% polyester is the best fabric choice. The more polyester in your fabric, the more vibrant your prints.

Source: Printful

Products

With DTF technology and sublimation you can print on a wide product range. Our DTFlex is already available on popular apparel staples and select accessories, including hats, polos, hoodies, and jackets. We’re actively expanding the product range, so expect more premium options soon. Let’s have a look at what products we offer at Printful.

Apparel

Sublimation is the go-to t-shirt printing method for custom shirts with all-over prints. At Printful, you can find shirts in different fits and styles, including sports jerseys, crew necks, tank tops, crop tees, and rash guards.

Sublimation is also perfect for sportswear items like swimwear and leggings, which can rock bold prints and vivid colors. You can choose from:

Although DTF print products are more limited, you can currently use the DTF process on a number of apparel items and accessories, like:

Home & living

Sublimation printing is a versatile method that allows for lots of creativity. It’s often used to print home decor items like blankets, custom mugs, cork-backed coasters, laptop sleeves, gaming mouse pads, and more.

The DTF printing method isn’t currently available for any of the home decor items, but stay tuned for updates in the future.

Quantity

If you’re seeking a printing technique that aligns with the print-on-demand model, both DTF printing and sublimation offer flexibility and convenience. With either method, you can easily print just one item at a time or handle larger bulk orders, making them adaptable to varying business needs.

Since there are no order minimums, you can experiment freely with new designs or products without worrying about maintaining inventory. This opens opportunities for creative freedom and reduces the financial risk of unsold stock, allowing you to test ideas and tailor your offerings to customer preferences.

Eco-friendliness

Both techniques allow printing one-offs, so you won’t have to worry about unsold stock and overproduction.

Printful’s DTFlex uses water-based inks and on-demand fulfillment, helping reduce waste and overproduction. Sublimation, meanwhile, is particularly efficient on polyester fabrics with minimal ink waste, making both strong choices depending on your sustainability goals.

When it comes to minimizing fabric waste, Printful’s all-over print products are cut & sewn in-house. The leftover fabric scraps are then used to create accessories like scrunchies and headbands.

On-demand fulfillment

DTF printing and sublimation are both excellent options for on-demand fulfillment, making them ideal for print-on-demand businesses. With both methods, you have the flexibility to produce one item at a time or fulfill bulk orders without the need to maintain inventory. This allows you to offer custom products without upfront investment in stock, reducing financial risk and waste.

At Printful, both direct-to-film and sublimation products are only made after an order is placed, ensuring that every item is created specifically for your customer. Whether you’re testing new designs or scaling up for larger orders, the ability to seamlessly switch between single-item and bulk fulfillment helps you adapt to varying demands. Plus, Printful offers discounts for bulk orders, which can reduce costs as your business grows.

Upfront investment

You won’t need an upfront investment if you partner with a print-on-demand (POD) company to sell direct-to-film or all-over print products. That’s because your items are made only when a customer orders them. You get money from your customers, pay for the product, and keep the profit.

If you want to print designs by yourself, be prepared to spend a lot on printing equipment, like sublimation printers or direct-to-film printers. In addition, you’ll need to source blank products, get special inks, and take care of shipping. It’s a large upfront investment, so it might be cheaper to dropship products with your designs using a POD provider.

What is DTF printing best for?

DTF is best for detailed, colorful designs on fabrics where other methods fall short. Think vibrant graphics on fleece hoodies, sharp logos on polyester blends, or durable prints on outerwear and hats. It delivers premium, retail-quality results on-demand.

DTF printing is also fairly quick compared to sublimation, which reduces production costs. Before deciding to sell items with DTF prints, it’s a good idea to test them and order one for yourself. You could also compare the same design fulfilled with other techniques.

What is sublimation printing best for?

Sublimation printing is a great option if you’ve chosen to dropship the products you sell because it’s one of the most popular printing techniques on offer.

Sublimation printing is the best option for garment printing. It allows you to print detailed, colorful artwork, photos, and patterns from seam to seam. If you want your designs to cover a garment fully, sublimation printing is the best option.

When branching out to selling accessories and home decor items, you can’t go wrong with this method. From mugs to coasters and blankets, sublimation printing is a popular technique for getting vivid results on different surfaces. Plus, it’s an eco-friendly choice.

DTF printing vs. sublimation: Which one will you choose?

In this post, you’ve learned about DTF and sublimation printing methods, their advantages and differences, and the type of products each method suits best.

Experiment with both methods to see what fits your brand — go bold with sublimation’s all-over prints or go precise with our DTFlex’s premium detail. Either way, your customers get products that look and feel professional.

Have you tried either of these printing methods? Share your experience with us in the comments!

Read next:

Sandra is a freelance writer and educator with a background in art and communication. She holds an MA in Art Museum and Gallery Studies, and in her free time enjoys reading, museum visits, and outdoor adventures.