Table of contents

The traditional fashion industry relies on assumptions – with manufacturers producing massive quantities of clothing months before a single sale is made. This system is the primary driver of global textile waste, sending millions of tons of garments to landfills annually.

On-demand manufacturing replaces this guesswork with precision. The on-demand model maintains profitability and eliminates unsold inventory because production only starts after a customer makes a purchase.

This article explores how this transition is building a more sustainable future for the global textile industry.

Key takeaways: Why on-demand manufacturing is the future of fashion

-

Elimination of overproduction: The on-demand model ensures production begins only after a purchase, effectively removing the risk of unsold products and excess inventory.

-

Drastic waste reduction: By producing only what is needed, on-demand production helps mitigate the staggering amount of textile waste currently sent to landfills.

-

Lowered environmental footprint: Utilizing digital printing and localized fulfillment reduces water consumption and carbon emissions throughout the supply chain.

-

Empowerment for smaller brands: Modern on-demand manufacturing gives smaller brands the digital tools to scale professionally without high minimum order quantities.

-

A more sustainable future: Moving away from mass production allows the textile industry to align with environmental responsibility and evolving customer preferences.

The true cost of fast fashion

The term fast fashion has become synonymous with rapid production cycles and low-cost garments. While it made trendy apparel accessible to the masses, the environmental price tag has been immense. The traditional supply chain is optimized for speed and volume, often at the expense of environmental responsibility.

Annual volume of textile waste in landfills

The equivalent of one garbage truck of textiles is landfilled or burned every second.

In the United States alone, the Environmental Protection Agency (EPA) estimated that 17 million tons of textiles were generated in a single year, with a significant portion ending up as landfill waste.

This staggering amount of discarded clothing is a direct result of failing to align apparel production with actual demand.

Environmental effects of the fashion industry's overproduction

Overproduction is the primary driver of fabric waste. When brands manufacture thousands of units to satisfy high minimum order quantities, they inevitably face the issue of unsold products.

As much as 40% of all new textiles manufactured for clothes are never sold, often ending up in incinerators or landfills before they ever reach a consumer.

These unsold goods represent a massive drain on valuable resources. The water used to grow cotton, the energy required for manufacturing, and the chemicals used in dyeing are all wasted when the final product is discarded without being worn.

Fast fashion’s impact on global ecosystems

The environmental impact extends beyond landfills. The textile industry is responsible for approximately 10% of global carbon emissions and 20% of global wastewater, according to data from the United Nations Environment Programme (UNEP).

When mass production happens in regions with lax environmental regulations, the discharge of untreated dyes into local waterways can devastate ecosystems. Furthermore, the reliance on synthetic fibers means that waste contributes to microplastic pollution, which persists for centuries.

Print on Demand as a sustainable production model

Print on Demand (POD) is a sustainable manufacturing strategy that uses digital tools to eliminate the inefficiencies of the traditional market.

Print on Demand prevents overproduction

The on-demand model only produces what is sold. This fundamental change removes the risk of unsold inventory. Instead of brands sitting on excess stock that eventually becomes textile waste, a POD partner like Printful produces items individually, ensuring every garment has a destination.

Minimizing inventory waste through on-demand production

Inventory management is a major hurdle for small businesses. Traditional methods require high upfront capital and lead to significant storage costs. By removing physical stock requirements, on-demand manufacturing helps entrepreneurs protect their cash flow while reducing textile waste.

The role of fashion-on-demand in sustainability

On-demand fashion represents a cultural shift toward intentional consumption. When consumers buy items that are made to order, they move away from the disposable mindset of fast fashion, supporting a system where every piece of clothing is created with a purpose.

Sustainability benefits of on-demand manufacturing

Adopting print-on-demand systems provides measurable progress for corporate sustainability efforts – and this is possible no matter how small your operations are.

Reducing global textile waste with on-demand systems

By matching production to demand, we address the root cause of clothing waste. When on-demand manufacturing becomes the industry standard, the global volume of unsold stock will decrease, taking the pressure off our landfills.

Lowering supply chain emissions through Print on Demand

A decentralized supply chain allows production to happen closer to the end consumer. Printful’s fulfillment centers in the US and Europe reduce shipping distances, lowering carbon emissions and mitigating supply chain disruptions.

Supporting conscious consumer behavior with sustainable choices

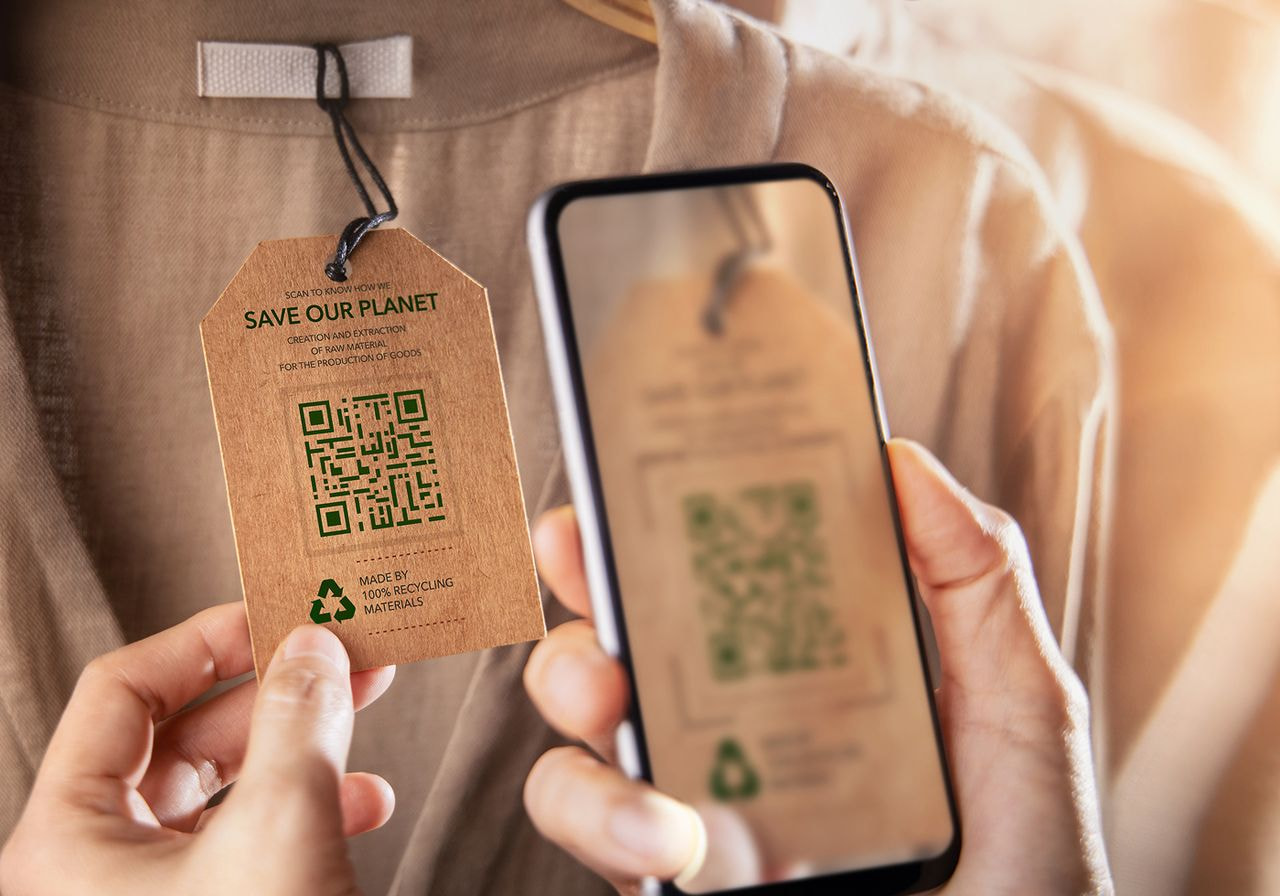

Buyers are increasingly aware of their ecological footprint. On-demand tech empowers brands to offer sustainable products without overproduction risks, delivering eco-friendly goods that meet consumer preferences.

How Printful supports sustainable fashion practices

Printful is at the forefront of helping brands build businesses that prioritize both growth and the environment. It’s about more than just producing clothes – it’s about providing the infrastructure for creating garments with purpose.

Eco-friendly materials and printing technologies at Printful

The choice of raw materials is vital. Printful offers a variety of products made from organic cotton and recycled polyester.

The use of digital printing – specifically direct-to-garment (DTG) technology – is more sustainable than traditional methods. DTG printing uses specialized water-based inks that are non-toxic and require significantly less water than screen printing or traditional dyeing.

Environmentally responsible supply chain strategies

Printful’s commitment to sustainability is baked into our operations. By focusing on high-quality manufacturing, we ensure that the clothes produced are durable and last longer, further reducing waste by slowing down the replacement cycle.

The integration of artificial intelligence (AI) into our Design Maker and fulfillment systems also helps reduce fabric waste by optimizing how designs are placed on the material.

Starting a sustainable brand with Printful's tools and services

For an entrepreneur, building a sustainable future starts with the right partners. Printful provides the digital tools necessary to launch a brand without the ecological footprint of a traditional fashion house.

-

No minimums: Start with zero excess inventory.

-

Global fulfillment: Reduce shipping distances worldwide.

-

Eco-conscious Catalog: Choose from a curated selection of eco-friendly pieces.

Challenges and the future of sustainable fashion

While on-demand manufacturing is a powerful solution, it’s part of a larger, ongoing shift toward a more circular economy.

Moving toward circular fashion systems

The long-term goal for the textile industry is a circular system where discarded clothing is recycled back into raw materials for new clothes.

On-demand production fits perfectly into this vision by ensuring that the initial volume of clothing introduced into the cycle is controlled.

Technology to reduce textile waste

Innovation in on-demand production continues to evolve. From made-to-measure sizing that reduces returns to advanced digital printing that uses fewer resources, the technology behind on-demand is getting greener every year.

As regulatory pressure on fashion companies increases to address their waste, these technical solutions are on track to become mandatory.

The future of zero-waste fashion manufacturing

We are moving toward a sustainable future where zero waste is not just a goal, but a standard. By combining clothing waste statistics with real-time demand, the industry can move away from the destructive habits of the past.

Manufacturing will become a precise, intentional act of creation.

Conclusion

By embracing print-on-demand manufacturing, brands can detach themselves from the wasteful cycles of mass production and fast fashion. This on-demand model is the most effective way to align business growth with environmental responsibility.

As we look toward a more sustainable future, the ability to produce only what is needed will define the next generation of successful, conscious fashion companies. Printful remains committed to providing the technology and tools necessary to make this vision a reality for every creator.

Frequently asked questions

Printful addresses textile waste by operating on a made-to-order model, meaning items are only produced when an order is placed. This removes the risk of unsold products becoming landfill waste.

Additionally, Printful uses digital printing technology that minimizes water usage and fabric waste during the production process.

While no manufacturing process is entirely impact-free, Print on Demand is significantly more sustainable than traditional mass production.

It eliminates excess inventory, reduces carbon footprint through localized fulfillment, and prevents waste associated with unsold inventory – a characteristic of the traditional fashion industry.

Printful offers a dedicated selection of eco-friendly products in our Catalog. These include items made from sustainable, recycled, or organic materials.

By choosing these raw materials, brands can ensure their apparel aligns with the latest sustainability standards and customer preferences for greener choices.

Yes, you can build a fully sustainable brand using Printful’s on-demand manufacturing service. By selecting eco-conscious products and leveraging our digital tools to avoid overproduction, you can provide your customers with high-quality garments while significantly reducing waste in your supply chain.

Fashion on demand is a production strategy where clothing is manufactured only after a customer purchases. This on-demand model contrasts with traditional retail, where items are made in bulk based on demand forecasts.

On-demand fashion allows for greater customization, faster response to trends, and a drastic reduction in global textile waste.

Published author, scholar, and musician, Andris draws on over 11 years of experience in and outside academia to make complex topics accessible – from SEO and website building to AI and monetizing art. Devoted to his family and self-confessed introvert, he loves creating things, playing musical instruments, and walking around forests.