Table of contents

Mug printing comes in many forms, each with its own strengths in durability, quality, and cost. So, what is the best method of printing mugs?

This guide explores sublimation, screen printing, heat transfer, UV printing, and engraving to help you find the right fit for your custom mug printing business or personal projects.

What makes a mug printing method the best?

Each printing method has different strengths, and the best choice for custom mugs comes down to four things – durability, print quality, cost efficiency, and material compatibility.

Let’s break these down.

Durability (dishwasher and microwave safe)

Durability is impacted by dishwashing, harsh detergents, abrasion from stacking, thermal shock, and microwave exposure.

A printed design that sits on top of the mug’s surface is more likely to peel or crack. Designs that become part of the coating or physically alter the surface last longer.

Sublimation printing infuses dye into the mug’s coating, making it resistant to heat, water, and daily wear. Laser engraving carves into the coating or material, creating a permanent mark that will not wash away. These methods are typically dishwasher safe, though metal and enamel mugs can’t be microwaved.

Tip: Need tips on designing mugs? Check out how to design your own mug on our blog.

Print quality (color vibrancy, intricate details)

High-quality results need designs that stand out. Sublimation printing and digital printing excel at producing vibrant colors, smooth gradients, and photo-level accuracy.

They capture design complexities like fine text or shaded logos that other printing techniques may lose.

In contrast, screen printing and pad printing are better suited to bold, limited-color graphics with crisp lines.

Cost efficiency (bulk vs small runs)

Pricing often determines the best printing technique for you. Screen printing is highly cost-effective when producing thousands of promotional mugs, since the initial setup pays off at scale.

Sublimation mugs and UV printing are ideal for short runs, customized products, or print-on-demand sellers, because they require little setup and keep costs low for one-offs.

Tip: Learn more about Print on Demand on our blog.

Material compatibility (ceramic, enamel, glass, steel)

Not every process works on every material. Sublimation printing requires a polymer coating on ceramic mugs and does not work on uncoated mugs.

UV printing is more flexible and can be tuned for glass and steel with the right primers or clear coats.

Laser engraving works across coated ceramics, stainless steel, and enamel because it physically alters the surface rather than depositing ink.

Popular mug printing methods explained

Here’s a breakdown of the most popular printing methods for mugs. We’ll cover how each technique works, what equipment it requires, and its best use cases.

Sublimation printing

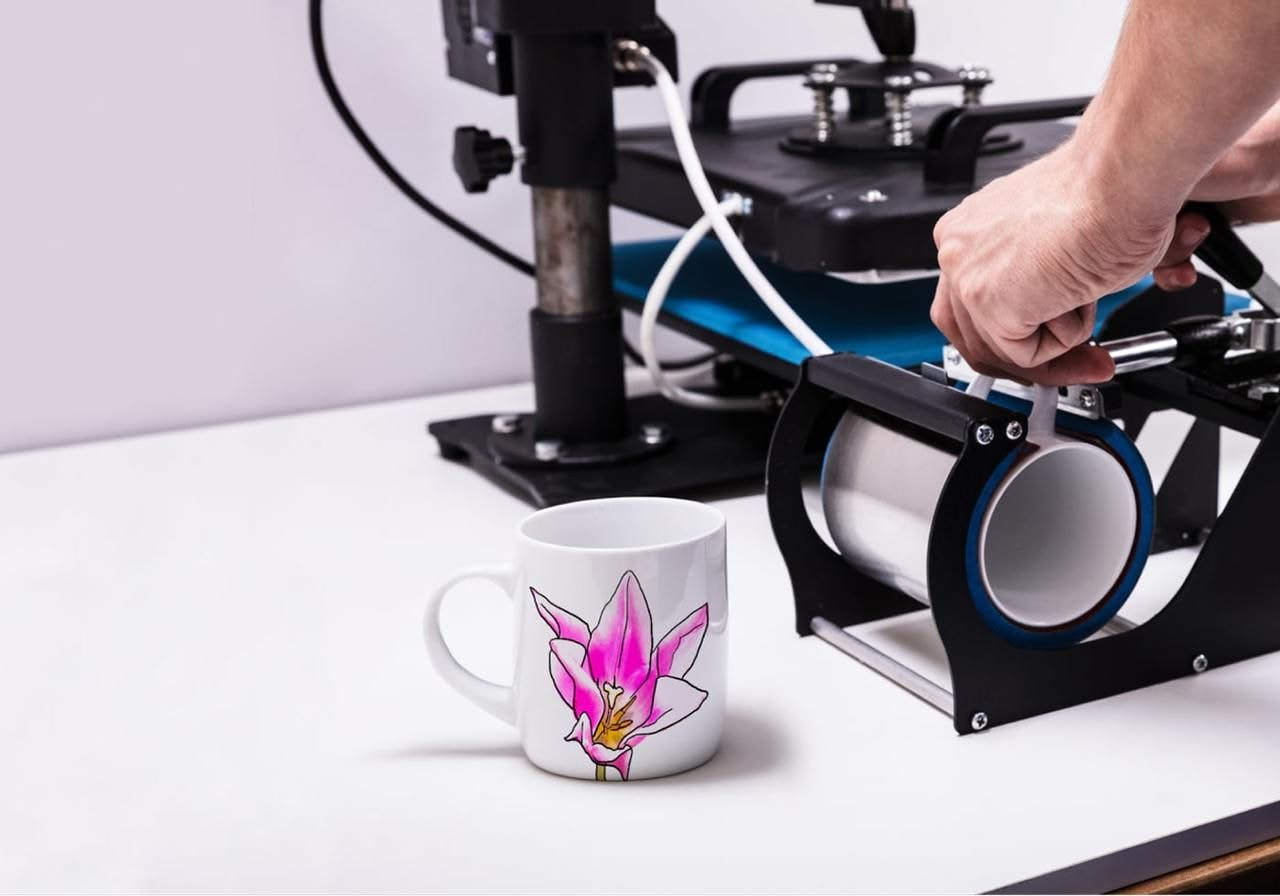

Sublimation transfer printing uses sublimation ink to print a mirrored design on sublimation paper. The print is wrapped around a polymer-coated mug and secured with heat-resistant tape, then pressed in a mug press or a convection oven.

Under heat and pressure, the dye turns to gas and diffuses into the mug’s polymer coating, creating a permanent image within the surface rather than on top of it. This process requires polyester or polymer-coated substrates and does not work on uncoated mugs.

Durability. Since the dye becomes part of the coating, the result is highly resistant to cracking, peeling, and fading. Many premium coated blanks, such as ORCA-coated mugs, are marketed as dishwasher and microwave-safe, with testing claims of thousands of dishwasher cycles. Always follow the supplier’s care guidelines.

Print quality. Excellent for vibrant colors, smooth gradients, photo wraps, and intricate designs. Since there’s no raised ink layer, the surface remains smooth and the printed design looks continuous around the curve.

Cost efficiency. A strong fit for small to medium runs. Setup is minimal beyond a sublimation printer, paper, and a heat press, so one-offs and quick batches are economical.

Compatibility. Best on ceramic mugs that have a polyester polymer coating. You can also sublimate on polymer mugs and certain metal drinkware that have a suitable coating. However, untreated stainless steel or glass without a compatible coating will not accept the transfer dye.

Tip: Looking for creative mug design ideas? Explore our article for inspiration.

Screen printing

In screen printing, a stenciled mesh screen sits over the mug while a squeegee presses ink through the open mesh areas to form the image.

Mugs are typically printed on rotary or cylindrical screen presses that keep turning for even coverage. Each color uses its own screen, so multicolor designs require separate screens and careful application.

Inks and curing. For drinkware such as coffee mugs, many use ceramic, organic, epoxy, or UV-curable inks. Curing can be done with UV, a low-temperature oven, or kiln firing. Properly cured ceramic or organic inks yield the toughest results and better dishwashing performance.

Durability. When inks are matched to the glaze and fully cured, screen printing holds up well for daily use. Manufacturers often position kiln-fired or high-temperature decal mugs as dishwasher and microwave-safe, while non-fired mugs may require gentler care depending on ink chemistry.

Print quality. Thanks to thicker ink deposits, expect bold, opaque spot colors and crisp lines. Halftones are possible, but photo-realistic images are usually better handled by sublimation printing or digital printing on mugs.

Cost efficiency. Setup involves screen making and press setup, so costs favor large batches. Once screens are ready, the per-unit cost drops significantly, and high-speed rotary systems can print thousands of pieces per hour, which is ideal for promotional mugs and long runs.

Compatibility. Screen printing works on glazed ceramic mugs and other cylindrical drinkware when the right ink and surface prep are used. Cylindrical presses are designed for mugs, glasses, and bottles, and can be configured for multi-color designs.

Heat transfer printing

Heat transfer printing uses a transfer sheet to apply the design under heat. It’s similar to sublimation but typically uses inks that sit on top of the surface.

Durability: Good, though less compared to sublimation. May peel or fade over time, especially if not sealed properly.

Materials and equipment. You will need special transfer paper for hard surfaces, a compatible laser or white-toner printer, heat-resistant tape to secure the sheet, and a mug press or convection oven.

Print quality: Very good – great for multi-color or photographic designs when high-resolution transfers are used.

Cost efficiency: Good for small batches or custom-printed mugs, though per-unit costs are higher than large-scale printing methods.

Compatibility. Designed for coated ceramic mugs and other smooth, non-porous substrates like glass or metal when the correct primer or paper is used. Unlike sublimation, it can work on items that are not polymer-coated.

Digital printing (including UV printing)

Digital printing skips the transfer sheet entirely. The design is printed directly onto the mug’s surface using specialized printers.

The ink is instantly cured with ultraviolet light, creating a durable print. This allows for highly detailed, photo-quality designs without the need for screens, films, or transfer papers.

Materials and equipment. You’ll need a UV flatbed or rotary printer that can handle hard surfaces. These printers use special UV-curable inks that harden instantly under ultraviolet light – no mug press required.

Durability. UV prints form a tough surface layer that resists scratches, fading, and moisture. While durability depends on the ink set and coatings used, well-cured UV prints are typically more resistant than standard heat transfers.

Print quality. Digital printing excels at full-color, high-resolution graphics, including gradients and fine details. UV printers can even produce raised or textured effects with multiple ink passes, which isn’t possible with sublimation or transfers.

Cost efficiency. Best suited for short runs, one-offs, and customization. Setup is fast, making it ideal for personalized gifts. However, equipment costs are high, so per-unit pricing is generally higher than sublimation or large-scale screen printing.

Compatibility. UV printing works on a wide range of materials like ceramic, glass, metal, wood, and even plastics – without requiring polymer-coated blanks. This versatility is a major advantage over sublimation, which is limited to coated substrates.

Other specialty methods

Not every project fits the usual approaches. When you need tiny logos on tricky curves, a premium etched finish, or kiln-fired decals, these specialty options can outperform standard methods.

Here are some cases where pad printing, laser engraving, and transfer decals might be the right solution.

1. Pad printing

A silicone pad picks up ink from an etched plate (cliché) and presses it onto curved or irregular areas of the mug. The pad conforms to the shape, which makes it useful for small logos and hard-to-reach surfaces.

Durability. Good when using two-part epoxy, UV, or ceramic inks that are fully cured. Dishwasher resistance varies by ink chemistry and curing profile.

Print quality. Results in sharp spot colors and fine lines on small areas. Not ideal for photo wraps or large full-bleed art.

Cost efficiency. Requires plates and setup, so it favors medium runs. Each added color needs its own plate and pass.

Compatibility. Works on glazed ceramic, glass, stainless steel, and enamel when matched with the right ink and primers, if needed.

2. Laser etching or engraving

A focused laser beam removes a thin layer of coating or marks bare metal, creating a precise, permanent design with no ink layer.

Durability. Very high. The mark will not peel or fade. Dishwasher and microwave safe on ceramic mugs.

Print quality. Extremely crisp line work and detailed designs. The lack of ink results in a monochrome look for a premium, minimalist finish.

Cost efficiency. Higher per-unit time than printing, but uses no inks or screens. Strong value for personalization and premium gifts.

Compatibility. Effective on coated ceramics, stainless steel, powder-coated drinkware, and enamel surfaces.

3. Transfer printing (historical and decal workflows)

Traditional transfer printing uses engraved plates to print ceramic inks onto transfer paper, which is applied to the mug and then fired in a kiln. Modern ceramic decals follow the same idea with screen-printed or digitally-printed decal sheets.

Durability. Excellent after proper firing. Generally dishwasher safe. Microwave suitability depends on the ink system and whether metallic pigments are present.

Print quality. High detail and rich color. Decals can cover complex shapes, though a slight edge or gloss difference may be visible at the boundary.

Cost effectiveness. Best for medium to large runs due to decal preparation and kiln time.

Compatibility. Optimized for glazed ceramic mugs and other ceramic drinkware.

Which mug printing method is right for you?

To help you decide what is the best method of printing mugs for your needs, here’s a quick guide.

Small businesses: Sublimation or digital

For sellers needing mug printing services, both sublimation and digital (UV) provide high-quality prints, vibrant colors, and support personalization.

Sublimation works well on coated ceramic mugs, while digital printing offers broader material compatibility.

Bulk promotional orders: Screen printing

If you need promotional mugs in large quantities, screen printing offers the best cost efficiency, especially for simple logos. It delivers bold, lasting results at scale.

Premium gifts: Engraving

For high-end or luxury gifts, laser etching or engraving gives a sleek, premium finish. Combining that with branded packaging delivers a lasting impression.

Print-on-demand sellers: Sublimation

For print-on-demand entrepreneurs, sublimation printing is a top choice. It has a fast turnaround, supports fine details and full-color designs, and is durable for customers.

Conclusion

Picking the best method of printing mugs depends on what matters most to you – durability, design complexity, cost, or material.

Choose sublimation printing if you want vibrant, photo-quality designs on ceramic mugs, or screen printing if you’re going for bulk orders. Want flexibility across materials? Choose digital (UV) printing.

Heat transfers are a solid mid-ground option, offering good quality and easy setup for smaller batches. Or, try specialty methods like pad printing or engraving, which work well for unique shapes and premium branding.

Whether you’re starting a mug printing business, expanding your custom design inventory, or adding the perfect mugs to your online store, there’s a method that fits your scale, style, and budget.

FAQs

If you’re going with the sublimation process, you’ll need a dedicated printer that uses special sublimation paper and ink, plus a mug heat press. For digital printing, a UV printer designed for mugs is ideal.

Screen printing, pad printing, and engraving require different specialized equipment.

Only if you choose to do sublimation printing. If you prefer screen printing, UV printing, or laser engraving, you’d need specialized printers or presses for those methods.

Skip the manual process altogether with Printify’s print-on-demand mugs. Try different mug materials and printing methods to get your ideal result – no upfront costs, no hassle.

Published author, scholar, and musician, Andris draws on over 11 years of experience in and outside academia to make complex topics accessible – from SEO and website building to AI and monetizing art. Devoted to his family and self-confessed introvert, he loves creating things, playing musical instruments, and walking around forests.