Table of contents

“I just want my t-shirts printed!”

You’ve probably heard this from someone starting their own t-shirt store. Perhaps you’ve even said it yourself.

The buzz you get from envisioning a design idea can wear off quickly once you’re faced with the more technical questions, the first one being—which apparel printing method should I choose?

There are quite a few custom apparel printing options out there, but the two most popular are direct-to-garment (also known as DTG printing) and screen printing. Choosing the right one for your online clothing brand can be the first building block that leads to satisfied customers, saves costs, and enables you to scale your business as it grows.

With so much at stake, it’s important to research your options and ask questions about the two printing techniques, such as:

-

Will my design work with it?

-

How cost-effective is it?

-

How sustainable is it?

In this article, we’ll look into the differences between DTG and screen printing technology, the designs the two printing methods work best with, and how sustainable each of them is.

What is DTG printing?

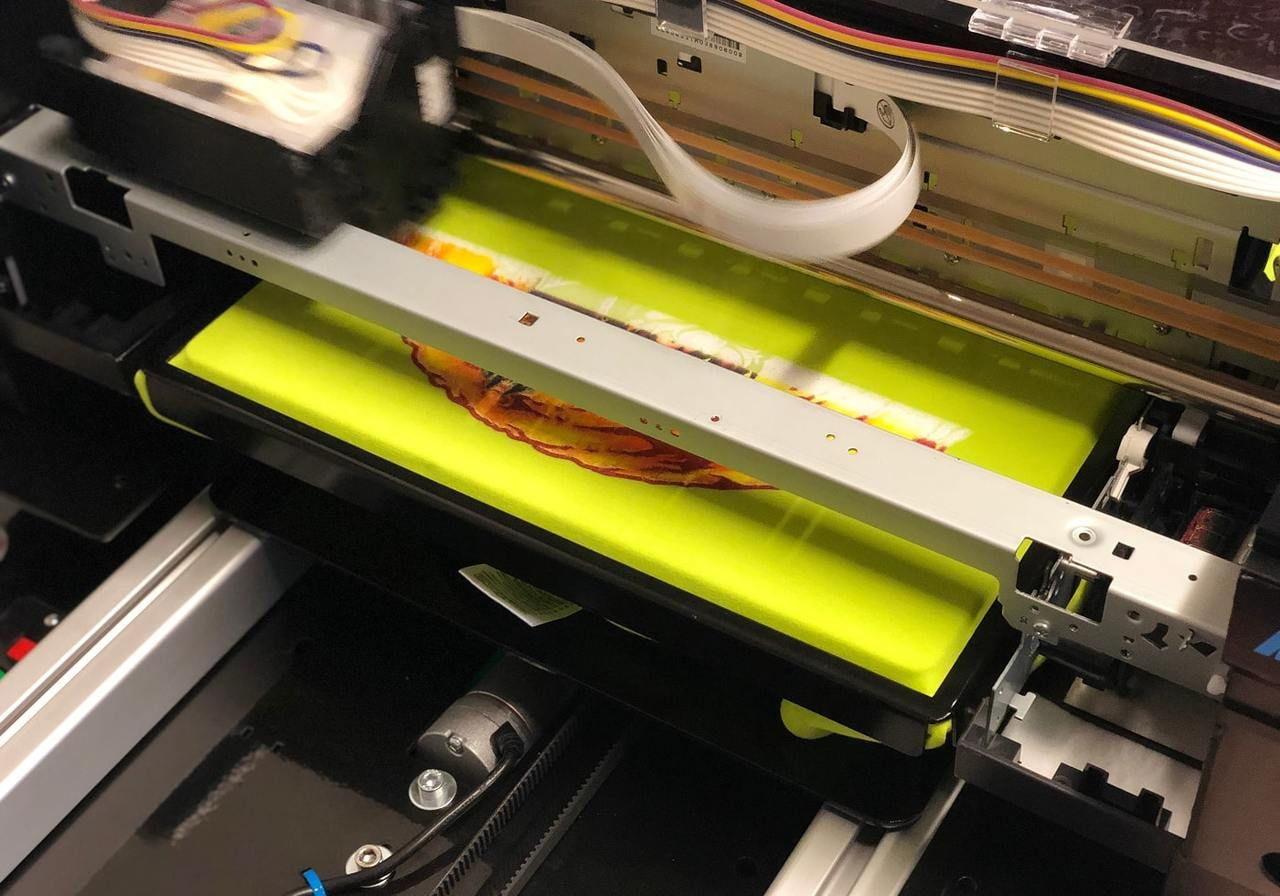

Direct-to-garment printing (DTG) is a printing technique where a garment is pre-treated with a bonding agent, and then ink is jetted directly onto the garment. The ink then soaks into the fibers of the garment, locking into them through the bond the pre-treatment makes between the garment and the ink. The process is similar to printing on paper.

Once printed, the garment is carefully removed from the printer and placed onto a conveyor dryer to evaporate the pre-treatment and cure the ink, resulting in a durable, lasting print that feels smooth to the touch.

The ability to print photorealistic images and fine details makes DTG printing ideal for complex designs that feature gradients or many different colors. Since the printing process is digital, there’s no need for extensive setup. This allows you to print items with minimal upfront investment when partnering with a print-on-demand provider, as products are only printed when ordered.

What is screen printing?

Screen printing is a printing method that involves pushing ink through a mesh stencil onto fabric. Each color in the design requires a separate screen, meaning multiple screens are needed for multicolored designs. The ink layer is usually thicker than with DTG printing, giving screen-printed t-shirts and other garments a thick, tactile feel.

The screen printing setup process is time-consuming as a separate screen needs to be prepared for each color. Once the screens are created, the printing process is fast and efficient, making bulk orders more cost-effective.

Valuable read: What is Screen Printing: Your All-in-One Roadmap

DTG vs. screen printing: Key differences explained

Choosing between DTG and screen printing comes down to key aspects like print quality, design complexity, and the ability to produce small or large quantities. Let’s examine how the two methods compare.

Print quality and durability

DTG prints offer exceptional clarity and detail, especially for complex designs with many colors or gradients. The ink bonds directly with the fabric, creating a soft feel and a lasting design that holds up after many washes.

Screen-printed garments are known for their durability due to the thicker layers of ink applied during the screen-printing process. These layers sit on top of the fabric, making the design highly resistant to wear, frequent washing, and abrasion. That’s why screen printing techniques are commonly used for workwear, uniforms, and other merchandise that requires long-term durability.

Print complexity

DTG printing excels at handling intricate designs. Compared to screen printing, where multi-color designs require setting up a separate screen for each color, a DTG printer produces the entire design at once, regardless of complexity.

Design complexity also doesn’t affect the product cost, making DTG printing ideal for businesses that need to offer a wide variety of designs.

Learn more: DTG vs. DTF Printing: Which Method Is Better for Your Designs?

Screen printing works best for solid graphics without small details. Think basic typography, geometric designs, symbols, and shapes. That’s because making stencils for intricate designs is time-consuming, and it’s difficult to get the details right during the printing process.

Since each color is applied separately, screen printing is also mostly used for designs with few colors. Print providers often limit how many colors you can have in your design, and usually, no more than 9 are allowed. Additionally, the product cost will depend on your design’s color count.

Color vibrancy

Both DTG printing and screen printing produce vibrant colors, but they achieve it differently. During the screen printing process, the ink is applied in thick layers, which can make designs pop, especially on darker fabrics. This makes it particularly effective for designs that use just a few colors or rely on strong contrasts.

DTG printing also offers excellent color vibrancy. DTG printing process allows a wide color range, and the inks are absorbed into the fabric, resulting in a smooth and natural finish. It’s especially effective for photorealistic or detailed images, maintaining color accuracy.

Fabric suitability

DTG printing works best on 100% cotton fabrics and cotton blends. Cotton lets the DTG ink soak into the fibers to produce soft results. This compatibility helps ensure prints hold up well over time with minimal fading.

DTG prints work on both light and dark fabrics, thanks to a pre-treatment process on darker garments. This pre-treatment ensures color vibrancy thanks to a white underbase.

Screen printing, in contrast, is highly versatile across fabric types. It works well both on cotton and synthetic materials like polyester, nylon, and performance blends—making it better for athletic wear and performance apparel. Screen printing also looks great on any color garment without the need for pre-treatment, as the thicker ink layers allow for high-opacity prints, even on dark materials.

With screen printing, specific inks are used on different materials, which causes the same graphic to appear differently depending on the fabric. DTG printing yields consistent results on both cotton and blend materials.

Sustainability

Compared to traditional screen printing, DTG printing reduces the risk of overproduction and minimizes textile waste. Since it supports on-demand printing with no order minimums, there’s less excess inventory and fewer unsold items ending up in landfills.

Plus, many DTG printer manufacturers—like Kornit, a Printful partner—create advanced tech with sustainability in mind, as it’s often the driving force behind the printing technique. Kornit’s DTG printing machines produce almost zero wastewater and use less energy, lowering the carbon footprint.

Kornit digital printers use water-based vegan inks formulated and tested in-house to maintain consistent quality. The inks are non-hazardous, toxin-free, biodegradable, and contain no animal by-products.

Screen printing can contribute to more waste, as it’s typically used for bulk ordering. Any unsold inventory could potentially go to waste and contribute to textile overproduction, which is one of the main problems the sustainable fashion movement is tackling.

Additionally, screen printing consumes more water and chemicals, particularly during the cleanup stage. Each screen used in printing needs to be washed and cleaned after use, requiring chemical solvents to remove the ink and clean the screens. This results in higher water consumption and chemical waste.

As a store owner, you must know how your business affects the environment. That’s why it’s important to consider the sustainability of each printing method.

On-demand fulfillment

DTG printing is the clear choice for on-demand fulfillment. Thanks to the short setup time, businesses can print single items or small batches with minimal upfront costs. This makes DTG printing a perfect fit for an online store connected to a print-on-demand dropshipping provider like Printful, where each item is printed only when ordered.

Once your customer orders a single t-shirt on your store, Printful automatically receives the order, prints your design on the t-shirt, and sends it directly to your customer under your brand. This on-demand printing model saves you from managing inventory or handling shipping logistics yourself.

You can still order in bulk if needed. Many print providers, including Printful, offer bulk discounts for DTG orders.

Screen printing, on the other hand, typically involves higher setup costs and minimum order requirements, so it’s better for large, one-time orders rather than on-demand production. It’s less flexible for businesses that don’t want to carry excess stock.

Considering screen printing in bulk for your company or party? Let us know and get a quote in 48 hours.

Upfront investment

The screen printing costs depend on the number of items you order. It’s often the cheapest option if you buy in large quantities, since it requires manual prep and separate screens that pay off when reused at scale.

That’s why screen printing has low bulk prices, but it’s less efficient for small runs. For low-quantity jobs, DTG printing is typically the more cost-effective solution.

Screen printing is budget-friendly for designs with simple graphics (ideally with only a couple of colors), but it requires an upfront investment. Most third-party print services have order minimums anywhere from 5 to 100 items.

The final price of your screen printing bulk order is based on the number of colors in your designs and the screens needed to print them. It’s financially challenging if you’re just starting out or want to experiment with designs.

Ordering in bulk also means managing storage and fulfillment of your custom t-shirts. This limits the number of designs on your store, because each design will have to be printed in bulk. With DTG printing, however, you can avoid this issue entirely by producing items as orders come in.

DTG vs. screen printing: when to choose which?

Both techniques have their strengths depending on the design you want to produce. Choosing the right printing method will lower costs, reduce waste, and improve turnaround times.

When to choose DTG printing

DTG printing is the better option for designs that feature photorealistic images, intricate details, or a wide color range. It’s also the right choice if you want to print small quantities or offer custom apparel on demand.

If your business frequently updates products or tests new designs, DTG printing gives you the flexibility to scale without investing in storage or inventory.

When to choose screen printing

Screen printing is ideal for simple, bold designs that rely on solid colors without any intricate details. It’s the go-to option for bulk orders, where costs can be offset by larger production runs.

If your design features basic graphics or typography and you need to print many items quickly and cost-effectively, screen printing is likely the best fit.

Read also: Embroidery vs Screen Printing: Which Should You Go With?

If it’s still hard to decide which printing method is right for you, take a look at this comparison table:

|

|

Screen printing |

DTG printing |

|

High-quality prints |

Yes |

Yes |

|

Detailed designs |

No |

Yes |

|

Unlimited color palette |

No |

Yes |

|

Order minimums |

Yes |

No |

|

On-demand fulfillment |

No |

Yes |

|

Bulk discounts |

Yes |

Yes |

|

Requires upfront investment |

Yes |

No |

It’s not just about cost—your printing method affects what you can sell, how you sell it, and how easily you can scale.

Choose your printing method wisely

Whether you go with DTG or screen printing depends on what you’re selling, how much you produce, and how flexible you want your setup to be. Before you make your final decision, consider:

- The amount of detail and colors in your design

- Whether you want small print batches or bulk

- How much time and money you want to invest upfront

- Whether you want to hold inventory or use an on-demand model

If you want to launch and grow with minimal risk, on-demand DTG printing is your best bet. With this printing method, it’s easy to introduce new designs to your store risk-free, and you don’t have to worry about keeping stock or shipping the items yourself.

Using DTG print providers gives you more time to experiment with your product offering and marketing. It also helps eliminate overproduction, thus minimizing waste.

What’s your experience with DTG and screen printing? Let us know in the comments below!

What’s your experience with DTG and screen printing? Let me know in the comments below!

Read next:

DTG printing vs. screen printing: FAQ

Choosing between DTG vs. screen printing depends on your design complexity and order volume. Screen printing is better for bulk orders and simple designs with solid colors. It uses screen printing presses and inks for durable, vibrant results.

Direct-to-garment printing (DTG) is better for detailed and intricate designs with multiple colors, especially for on-demand printing with minimal setup time. For small runs and custom apparel, DTG is the best cost-effective choice.

The screen printing process is better for longevity. The thick ink and layering used in silk screen printing create prints that withstand hundreds of washes.

Direct-to-garment printing with DTG printers produces high-quality prints but may fade sooner, especially on synthetic materials. If long-lasting, vibrant colors matter most, screen printing techniques are usually the right printing method.

Direct-to-garment is perfect for custom apparel with intricate designs and on-demand printing, but it has drawbacks. DTG ink isn’t ideal for synthetic materials, and light prints may fade faster than screen printing ink.

When comparing DTG vs. screen printing, you’ll also see that setup costs per print are higher for DTG on bulk runs. Additionally, direct-to-garment printing can’t always match the vibrant colors or durability of the screen printing process for solid colors.

Direct-to-garment printing uses specialized inkjet technology to print full-color, detailed, and intricate designs directly onto fabric. It’s perfect for on-demand printing and custom apparel businesses.

Screen printing involves pushing screen printing ink through a mesh printing press. It’s great for bulk runs, vibrant colors, and durability. The right printing technique depends on design complexity, order size, and cost.

The best method of t-shirt printing depends on your goals. For high-quality prints with bright colors on large orders, the screen printing process is the industry standard, offering cost-effectiveness and durability. For custom apparel with intricate designs or multiple colors and quick turnaround, direct-to-garment printing (DTG) is ideal.

Both DTG and screen printing methods have advantages. DTG is flexible and requires minimal initial setup time and costs, while screen printing presses are better for bulk consistency.

By Baiba Blain

With 7+ years of experience in translation and creative writing, Baiba now leads a squad of talented writers, balancing research-backed storytelling with team guidance, quality assurance, and SEO processes. Outside of work, she enjoys exploring old castles, spontaneous road trips, and talking back to her cats. 10/10 arguments won so far.